RINGSPANN has been developing and manufacturing Precision Clamping Fixtures for workholding applications for over 75 years. Over the past decades we have realized thousands of applications and numerous technically sophisticated solutions.

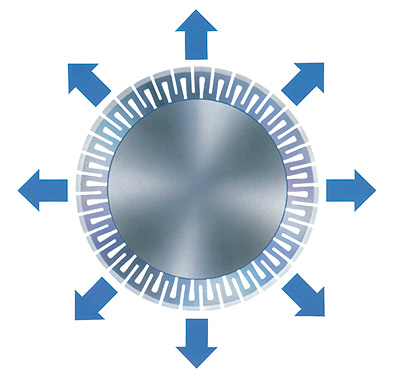

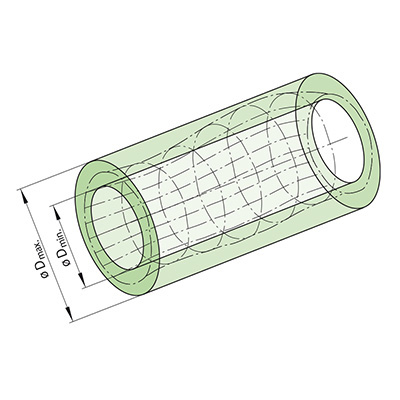

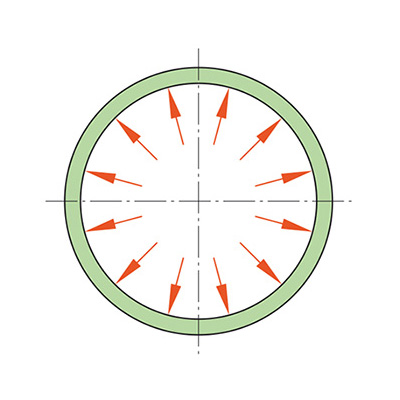

RINGSPANN specialized in clamping and centring on cylindrical internal and external surfaces. Typical components include automobile, gear and aircraft components.

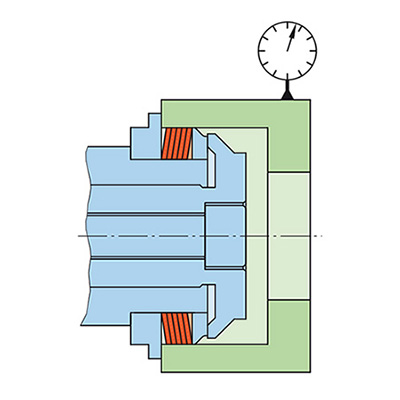

We have developed the RINGSPANN system on the basis of the RINGSPANN Clamping Disc, which encompasses

- Complete Clamping Fixtures, ready-to-use and

- Clamping Elements and components for customer assembled Clamping Fixtures

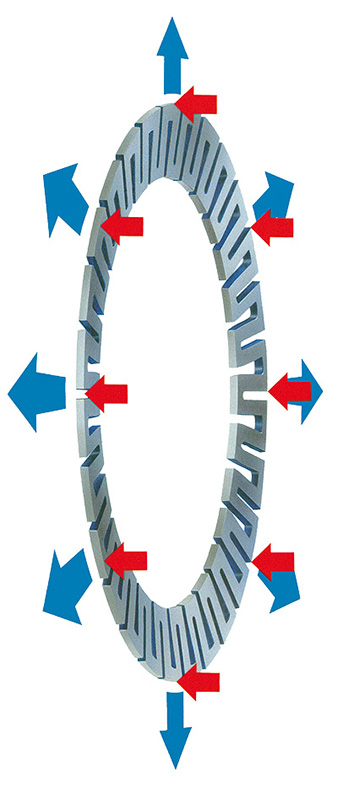

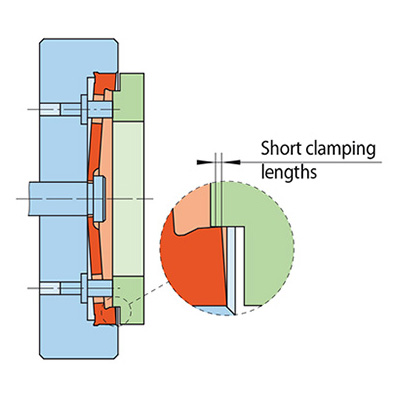

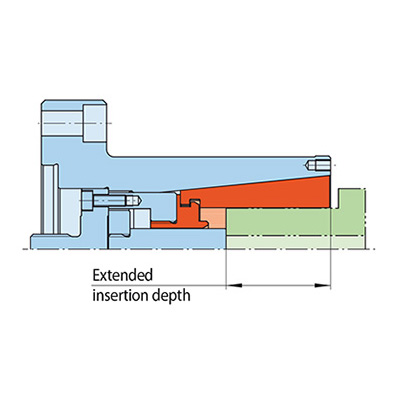

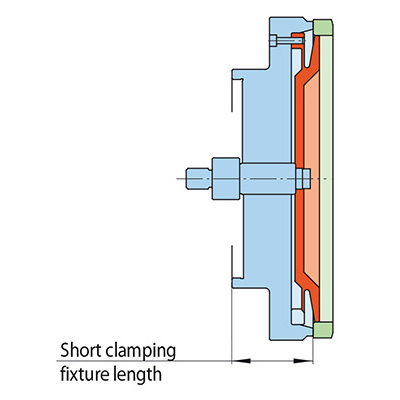

The RINGSPANN system offers the right solution for each clamping application and guarantees maximum clamping precision without the need for complicated alignment. This enables customers to achieve difficult objectives, such as clamping in short lengths or clamping thin-walled components that are susceptible to

deformation.